The three-layer PE anti-corrosion structure of the pipeline: one layer of epoxy powder (FBE100um), the second layer of adhesive (AD) 170250um, and the third layer of polyethylene (PE) 2.53.7mm. The three materials are integrated and firmly combined with the steel pipe to form an excellent anti-corrosion layer.

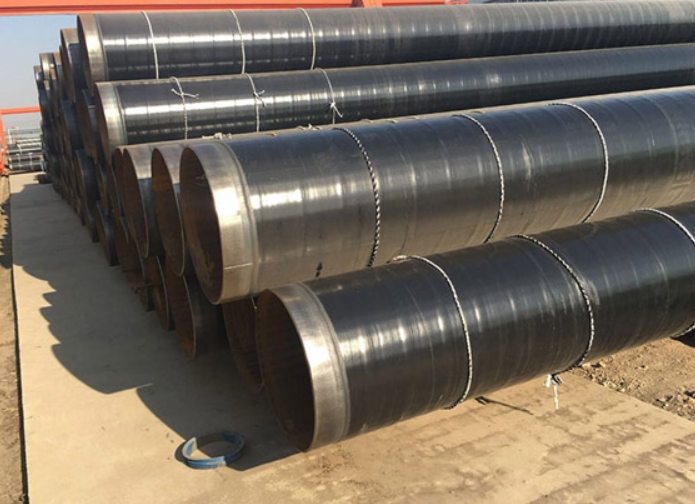

Pipe diameter range 600mm-1420mm

The pipeline has a two-layer PE anti-corrosion structure, one layer of adhesive (AD), and the second layer of polyethylene (PE). The two materials are integrated into one. The thickness of each layer is the same as the three-layer PE standard: ISO 21809-3:2016 and NACE RP0394- 2002 Technical Standard for Polyethylene Anti-corrosion Coating of Buried Steel Pipes ISO 12944-5:2007, ASTM D2513-18, EN 10285:2002 Technical Standard for Polyethylene Anti-corrosion Coating of Buried Steel Pipes

The single-layer PE anti-corrosion steel pipe uses a shower coating process (also known as the tomb curtain method) to rotate the steel pipe after medium frequency heating. The top layer of the steel pipe is a container containing polyethylene powder, which is sprayed on the outer wall surface of the steel pipe to form a polyethylene coating. layer. Implement standard awwa c210 water supply plastic coated composite steel pipe.

You must be logged in to post a comment.