Carbon steel pipe is a type of pipe made primarily from carbon steel, which contains carbon content in the range of 0.12% to 2.04%. This material is chosen for its high strength, durability, and resistance to compression, making it an ideal choice for transporting fluids and gases, including natural gas. The purpose of carbon steel pipe in the context of natural gas transportation is to provide a secure and efficient means of moving this essential fuel from its source to homes, businesses, and power plants.

Natural gas is a vital energy source for heating, cooking, and power generation, making its transportation a critical aspect of modern infrastructure. Efficient and reliable transportation of natural gas is essential to meet the growing demand for this fuel around the world. Carbon steel pipe plays a crucial role in this process, offering a cost-effective and durable solution for moving natural gas over long distances.

Carbon steel pipe is a fundamental component of natural gas transmission systems, including pipelines that crisscross countries and continents. These pipelines are designed to withstand the high pressures and temperatures required to transport natural gas efficiently and safely. The use of carbon steel pipe in natural gas infrastructure ensures that natural gas can be transported effectively, supporting the energy needs of communities and industries.

Carbon steel pipes are renowned for their exceptional strength and durability, making them an indispensable component in the natural gas industry. The primary element that contributes to this attribute is the carbon content within the steel, which enhances its tensile strength and fatigue resistance.

As a result, carbon steel pipes can withstand the high pressure and challenging environmental conditions commonly encountered in natural gas transmission systems. Moreover, their durability ensures a long service life, reducing the frequency of maintenance and replacement, thereby optimizing operational efficiency.

Corrosion is a significant concern in the transportation of natural gas, as it can lead to pipe failures and leaks. Carbon steel pipes are designed to mitigate this issue, thanks to their excellent corrosion resistance properties.

The composition of carbon steel, which typically includes alloying elements such as chromium, nickel, and copper, forms a natural oxide layer that protects the pipe’s surface from further corrosion. This layer acts as a barrier against chemical reactions with the transported gas and the surrounding environment, ensuring the integrity of the pipeline system.

Economic considerations are paramount in the natural gas industry, and carbon steel pipes offer a cost-effective solution compared to other materials. The wide availability and abundance of iron and coal, the primary raw materials for producing steel, contribute to its affordability. Additionally, the manufacturing process of carbon steel pipes is well-established, resulting in economies of scale that further reduce costs.

Their high strength-to-weight ratio also allows for thinner walls, which can reduce material costs without compromising structural integrity. These factors make carbon steel pipes a budget-friendly choice for natural gas pipelines, particularly for large-scale projects.

The weldability of carbon steel pipes is another significant advantage they offer. Carbon steel can be successfully welded using various techniques, such as electric resistance welding, submerged arc welding, and flux cored arc welding, among others. This versatility allows for the precise joining of pipes, ensuring a tight and secure seal that is essential for the safe and efficient transmission of natural gas.

The compatibility of carbon steel with different welding methods also increases the efficiency of construction and installation processes, as contractors can choose the most suitable technique based on specific project requirements and environmental conditions. Furthermore, the ability to weld carbon steel pipes effectively ensures that repairs and maintenance can be carried out promptly and efficiently, minimizing downtime and disruption to natural gas operations.

The manufacturing process of carbon steel pipes starts with the careful selection of raw materials, specifically carbon steel grades. Carbon steel is a versatile material that offers excellent strength and durability. There are several grades of carbon steel available, each with its own unique properties and suitability for different applications.

The selection of the appropriate carbon steel grade depends on factors such as the operating conditions, pressure requirements, and temperature range of the natural gas transmission system. Commonly used carbon steel grades for natural gas pipelines include ASTM A53, ASTM A106, API 5L, and API 5CT.

These standards define specific requirements for chemical composition, mechanical properties, and dimensional tolerance to ensure the quality and integrity of the pipes. The choice of carbon steel grade also considers factors such as resistance to corrosion and high-temperature environments.

There are two primary forming methods employed in the production of carbon steel pipes: seamless and welded. Seamless Pipes: Hot Rolling or Cold Drawing Process

Seamless pipes undergo either a hot rolling or cold drawing process to shape them into cylindrical tubes without any seams. In the hot rolling process, a solid billet is heated to high temperatures until it becomes malleable.

It is then pierced through a mandrel to create a hollow tube shape. This method produces seamless pipes with superior strength due to their refined grain structure.

Alternatively, cold drawing involves pulling a heated billet through a series of dies at room temperature to gradually reduce its diameter while increasing its length. Cold-drawn seamless pipes offer improved dimensional accuracy and surface finish compared to hot-rolled ones but may have slightly lower mechanical properties. Welded Pipes: Electric Resistance Welding or Submerged Arc Welding

Welded carbon steel pipes are manufactured by joining two pieces of flat plate or strip through various welding techniques. Two commonly used methods include electric resistance welding (ERW) and submerged arc welding (SAW).

ERW involves passing an electric current through the edges of two plates or strips placed in close proximity, causing them to melt together under pressure. This method is widely used for smaller diameter pipes due to its efficiency in high-volume production.

On the other hand, SAW involves submerged arc welding under a blanket flux layer that protects molten metal from oxidation during fusion. SAW is typically employed for larger diameter pipes used in heavy-duty applications like transmission lines.

Both seamless and welded manufacturing processes have their merits depending on factors such as cost considerations, project specifications, pipeline size requirements, and operational demands.

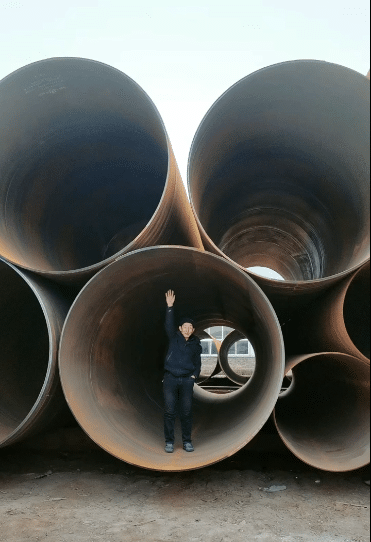

When it comes to carbon steel pipes used for natural gas transportation, there are several standard sizes available. These sizes are determined based on the diameter and wall thickness of the pipes. Commonly used diameters range from 1/8 inch to 48 inches, while wall thicknesses vary from Schedule 10 to Schedule XXS.

The schedule number indicates the wall thickness of the pipe, with higher schedules representing thicker walls. The diameter of a carbon steel pipe is an essential specification as it determines the flow capacity and pressure rating of the pipeline system.

Smaller diameter pipes with thinner walls are typically used for lower-pressure applications, such as distribution lines within cities or residential areas. Larger diameter pipes with thicker walls are employed for high-pressure transmission lines over long distances.

In the natural gas industry, certain pipe sizes have become more prevalent due to their suitability for specific applications. For instance, one common size used in the industry is 6-inch diameter pipes with a Schedule 40 wall thickness.

These pipes strike a balance between cost-effectiveness and durability, making them ideal for medium-sized distribution lines. Another commonly employed size is 16-inch diameter pipes with a Schedule 80 wall thickness.

These larger pipes are often utilized for high-pressure transmission lines that require enhanced strength and resistance to external forces. They can safely transport significant volumes of natural gas over extensive distances while maintaining structural integrity.

Transmission lines play a crucial role in delivering natural gas from production areas to end-users or distribution networks. To accommodate the substantial flow rates required, large-diameter carbon steel pipes are employed in these pipelines.

Sizes ranging from 24 inches up to 48 inches or even larger can be found in transmission systems. These large-diameter carbon steel pipes possess robust construction properties that allow them to withstand high pressures and handle significant volumes of natural gas efficiently.

The design considerations take into account factors such as internal pressure loads, external forces like soil weight or seismic activity, and safety regulations governing pipeline construction. By utilizing these large-diameter pipelines effectively along vast distances, natural gas companies can maximize efficiency in their transportation systems while ensuring a reliable supply of this vital energy source reaches consumers across regions.

Epoxy coatings are a popular choice for protecting carbon steel pipe used in natural gas applications. These coatings consist of epoxy resins mixed with curing agents, which form a strong and durable protective layer on the inner surface of the pipe.

Epoxy coatings provide excellent corrosion resistance, preventing the formation of rust and reducing the risk of leaks or failures in the pipeline. Moreover, these coatings offer good adhesion to the pipe surface, ensuring long-lasting protection even in harsh environmental conditions.

Cement mortar lining is another effective method to protect carbon steel pipes used for natural gas transmission. In this process, a layer of cement mortar is applied to the inner surface of the pipe by spinning or centrifugal casting.

The cement mortar creates a smooth and corrosion-resistant barrier that protects against internal abrasion and chemical reactions with gases or liquids carried by the pipeline. Additionally, cement mortar linings can provide improved hydraulic characteristics, reducing friction losses and optimizing flow efficiency within the pipe.

Fusion-bonded epoxy (FBE) coating is commonly applied as an external protection method for carbon steel pipes in natural gas infrastructure. FBE coatings are thermosetting polymers that adhere tightly to the pipe’s surface when heated during application.

These coatings offer exceptional resistance to corrosion caused by moisture, chemicals, and soil conditions. FBE coatings also provide mechanical protection against scratches or damages during transportation and installation processes.

Polyethylene tape wrapping is an easy-to-apply protective coating method widely employed for carbon steel pipes used in natural gas transmission systems. This technique involves wrapping multiple layers of polyethylene tape around the external surface of the pipe, ensuring complete coverage and sealing any potential openings or imperfections on its surface. Polyethylene tape wraps not only shield against corrosion but also act as a barrier against moisture ingress from surrounding environments.

Coal tar enamel coating has been traditionally utilized as an external protective measure for carbon steel pipes due to its high resistance to water absorption and excellent adhesion properties. This coating consists of alternating layers of coal tar-based primer and enamel topcoat that are heat-fused onto the pipeline’s outer surface using a hot-pour technique.

Coal tar enamel offers robust protection against soil corrosivity while providing exceptional mechanical strength against impacts or abrasions. These various coating methods serve as crucial defense mechanisms against corrosion damage that can compromise both safety and efficiency within natural gas pipelines constructed from carbon steel materials.

When it comes to installing carbon steel pipes for natural gas, safety should always be the top priority. Proper installation practices ensure the integrity of the pipeline and minimize the risk of accidents or leaks. Before starting any installation work, it is essential to have a detailed plan that includes thorough risk assessments and adherence to industry standards.

Trenching and laying procedures play a crucial role in the successful installation of carbon steel pipes for natural gas transportation. Firstly, trenches need to be carefully excavated at appropriate depths based on factors like soil conditions and pipe diameter. The trench’s width should allow enough space for workers to ensure proper pipe alignment during laying.

Once the trench is prepared, a bedding material should be placed at its bottom to create a stable foundation for the pipeline. This material helps distribute loads evenly and protects the pipe from potential damage due to external forces.

After placing the pipe in position, backfilling begins gradually while ensuring proper compaction at regular intervals. This process prevents excessive settling or movement of the pipe.

Proper jointing methods are crucial for maintaining structural integrity and preventing leakage in carbon steel pipelines. There are several techniques available, including welding (both butt welding and socket welding), mechanical joints, flanged connections, compression fittings, or threaded connections.

Welded joints offer excellent strength but require skilled welders trained in accordance with industry standards. Mechanical joints provide ease of assembly/disassembly but may require periodic maintenance checks.

Flanged connections allow easy disconnection when necessary but must be properly bolted to avoid leaks. Compression fittings are quick to install but may require occasional inspection due to possible wear over time.

Backfilling is an essential step after laying carbon steel pipes as it helps provide stability and support while protecting against external forces such as soil movement or traffic loads. The backfill material needs careful consideration based on local regulations and soil characteristics. The backfill material should be non-corrosive, free from debris that could damage the pipeline’s exterior coating or surface finish, adequately compacted without excessive compaction pressure that could lead to deformation or stress on the pipes.

Regular inspections throughout a pipeline’s lifespan are vital for ensuring its safety and reliability in transporting natural gas. Two primary inspection techniques used are visual inspection and non-destructive testing methods.

Visual inspection involves visually examining both internal and external surfaces of exposed sections of the pipeline network while looking for signs of corrosion, cracks, dents or other physical damages that might compromise its structural integrity. Non-destructive testing (NDT) methods such as ultrasonic testing (UT), magnetic particle testing (MPT), radiographic testing (RT), or electromagnetic testing (ET) provide more detailed insights into potential defects within walls without damaging or interfering with operation continuity.

Safe installation practices such as thorough planning, adherence to industry standards along with proper trenching procedures contribute significantly towards maintaining integrity during carbon steel pipe installations for natural gas transportation projects. Jointing methods need careful selection based on specific project requirements—identifying suitable backfill materials coupled with employing correct compaction techniques help prevent damages caused by external forces.

Regular inspections using visual examination alongside non-destructive testing methods ensure early detection of potential defects promoting safer operations throughout their service life. By following these guidelines diligently when working with carbon steel pipes for natural gas applications ensures not only efficient transportation but also helps safeguard public safety while contributing towards meeting energy demands sustainably

You must be logged in to post a comment.