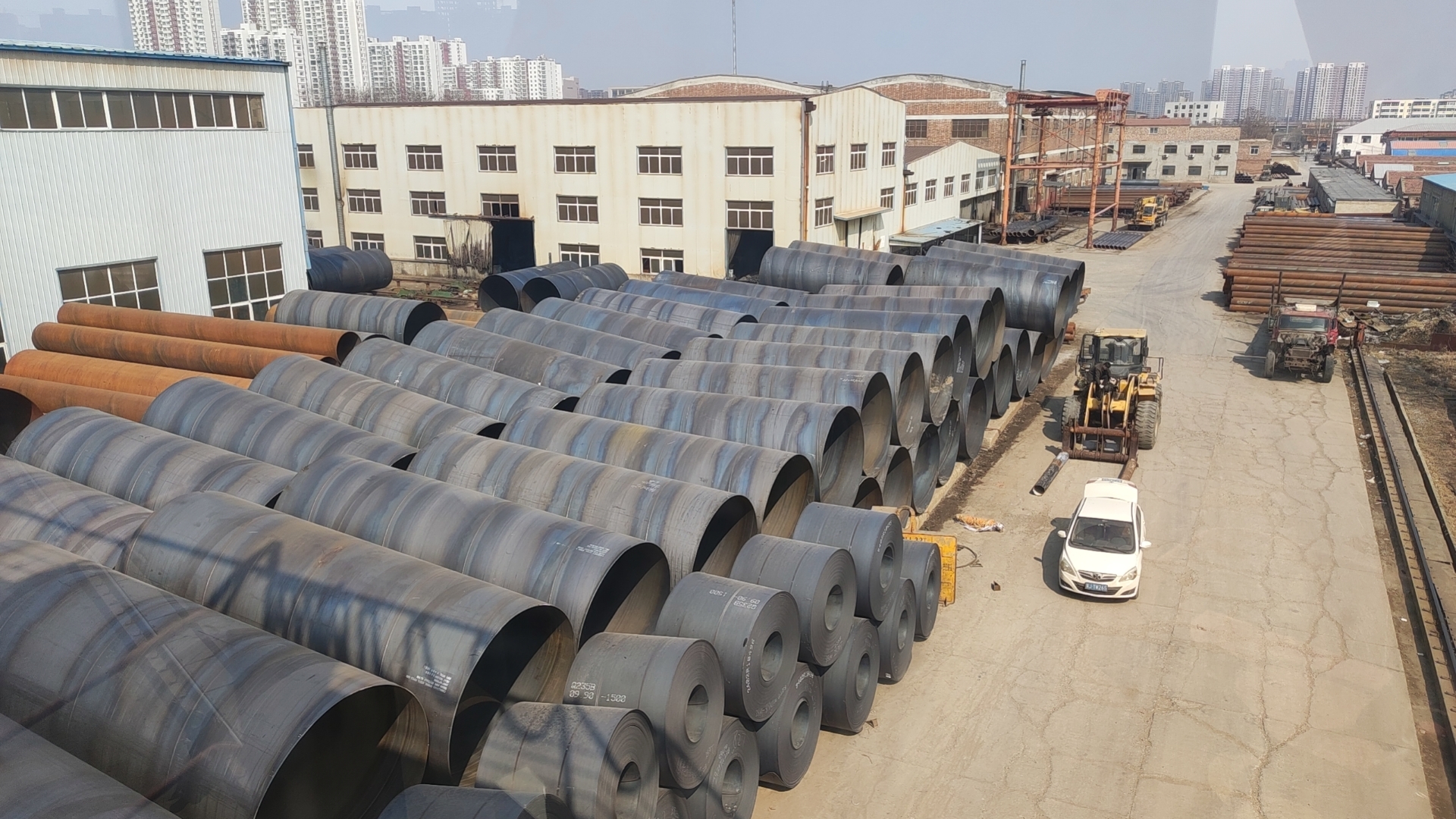

Production

Before the production of large-diameter spiral steel pipes, the strip is fed into the welded pipe unit and rolled by multiple rollers, and the strip is gradually rolled up. To form a circular tube blank with an opening gap, the roller reduction amount should control the weld gap to 1~3mm, and align both ends of the weld. The coiled plate is spirally formed by the forming machine, followed by internal and external submerged arc welding, and then spirally welded steel pipes of different standards and diameters are processed.