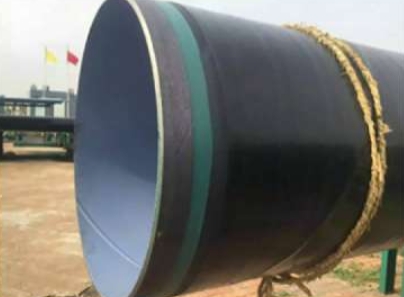

HDPE lined pipe is a three-layer polyethylene-coated anti-corrosion spiral welded pipe. It combines the high strength of spiral welded pipes with the coating and anti-corrosion technology of three-layer polyethylene. It is widely used in petroleum, natural gas, chemical industry, urban water supply and other fields.

This article will elaborate on the structural characteristics and advantages, application fields, market prospects and challenges of high-density polyethylene lined spiral welded pipe.

The structural characteristics of the three-layer polyethylene external (HDPE) lined spiral welded pipe are mainly reflected in the design of its anti-corrosion layer.

It adopts a three-layer structure, from inside to outside:

The first layer is a fused epoxy powder coating. The main function of this layer is to form a dense barrier to effectively isolate the steel pipe from the corrosive medium in the soil;

The second layer is the adhesive layer, which can tightly bond the steel pipe and the outer polyethylene layer together to improve the anti-corrosion performance of the entire pipeline;

The third layer is the polyethylene outer sheath, which has good chemical corrosion resistance and mechanical properties. It can resist the erosion of the external environment and protect the long-term stable operation of the pipeline.

Three-layer polyethylene coating technology is an advanced anti-corrosion technology. Its advantages are mainly reflected in the following aspects:

Three-layer polyethylene lined spiral welded pipe has significant advantages in the fields of energy transportation such as oil and natural gas.

First of all, it can effectively resist the erosion of underground corrosive media, extend the service life of pipelines, and reduce maintenance and replacement costs.

Secondly, its good mechanical properties can ensure the safe and stable operation of pipelines in complex underground environments and reduce potential safety hazards such as leakage.

In addition, high-density polyethylene lined welded pipes also have excellent weather resistance, wear resistance and anti-aging properties, and can adapt to various harsh underground environments.

In addition to applications in the fields of oil and natural gas, three-layer polyethylene lined spiral welded pipes are also widely used in chemical industry, urban construction and other fields.

In the chemical industry, it can effectively prevent corrosion of pipelines by chemical media and ensure production safety; in urban construction, it can be used in water supply, drainage and other pipeline systems to improve the durability and reliability of urban infrastructure.

With the continuous development and progress of the industrial field, the demand for high-performance pipe materials is also increasing. Therefore, as a high-performance pipe material, three-layer polyethylene coated steel pipe has very broad prospects for future development.

First of all, with the increasing awareness of environmental protection, the demand for corrosion-resistant, wear-resistant, and high-temperature-resistant pipeline materials will continue to increase.

Secondly, with the continuous advancement and innovation of science and technology, the manufacturing process and performance of high-density polyethylene coated straight seam steel pipes will continue to be improved and improved.

In addition, as the global market continues to expand and demand increases, the industrial scale of this material will also continue to expand.

First of all, its production process is relatively complex and requires high equipment and technology, which increases production costs to a certain extent.

Secondly, although the three-layer polyethylene lined spiral welded pipe has excellent anti-corrosion properties, problems such as damage to the anti-corrosion layer may still occur in extremely harsh underground environments, requiring regular inspection and maintenance.

In short, as a high-performance pipeline material, three-layer polyethylene coated steel pipe has excellent corrosion resistance, wear resistance, high temperature resistance and chemical media erosion resistance, and is widely used in petroleum, natural gas, chemical industry, etc. , water treatment and other fields. With the continuous development and progress of the industrial field, this material has very broad prospects for future development and will be more widely used and promoted.

Cangzhou DoubleDragon Steel Pipe Co., Ltd., based in China, specializes in manufacturing spiral welded steel pipes ranging from 8 to 140 inches in diameter and 6 to 26mm in wall thickness. Additionally, we offer options for coating and lining. With thirty years of experience, we offer expertise in production. We invite global friends to connect and inquire.

You must be logged in to post a comment.